Today’s manufacturing is much more complex than it used to be. Complex supply chains, hybrid teams, changing compliance requirements, and demanding customers are among the challenges manufacturers must address simultaneously.

Despite that, the majority of factories continue to rely on disconnected tools such as multiple HR systems, standalone CRMs, manual spreadsheets, and unlinked communication channels.

This disintegration hampers workflow, narrows the scope for seeing things from a higher perspective, and causes errors that could be easily prevented.

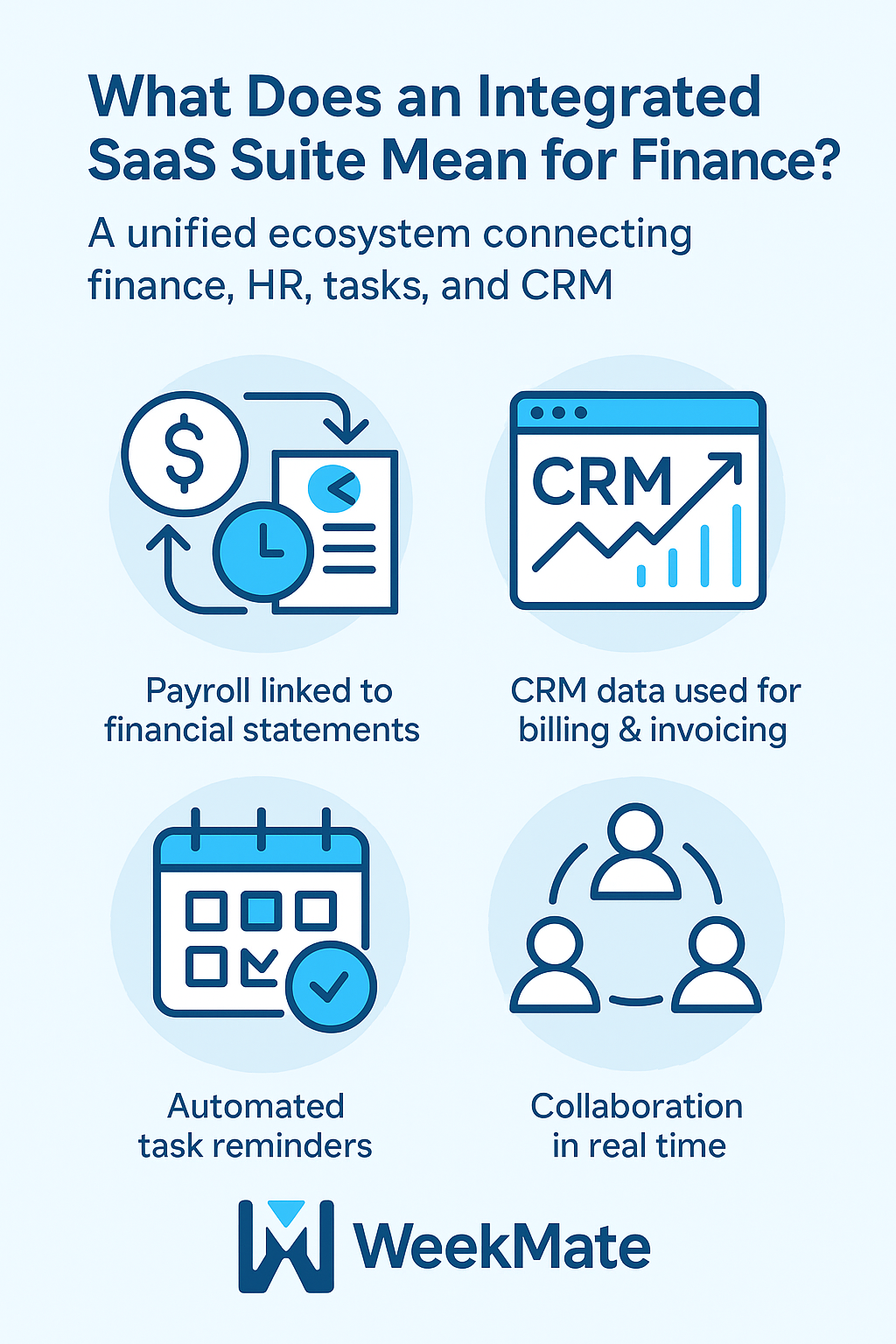

The solution is integrated SaaS for manufacturing — a 360° approach that connects the workforce, operations, tasks, clients, and communication in a single, digitally linked environment.

Weekmate offers manufacturers the power of a single, integrated platform that combines HRMS, e-CRM, e-Connect, and TaskHub to not only facilitate production but also business management.

The Problem: Disconnected Tools that Lead to Disjointed Operations

Manufacturers have a hard time when their systems are not compatible with each other:

- HR systems operate independently of production and maintenance activities.

- Communication is happening in parts through emails, spreadsheets, and chat apps.

- CRM tools cannot access production schedules or delivery updates.

- Supervisors use paper and pencil to keep track of attendance, tasks, and deadlines.

- Teams do not have a merged view of operations and customer expectations.

This fragmentation results in miscommunication, slower decision-making, and an increased manual workload.

A unified manufacturing platform eliminates these barriers by integrating HR, operations, CRM, and communication into a single digital ecosystem.

The Actual Meaning of “Manufacturing 360°”

Manufacturing 360 is a comprehensive, data-centric approach that integrates people, processes, equipment, and customers into a single network. Unlike standalone manufacturing management software, this concept emphasizes:

- Uninterrupted view

- Instant collaboration

- Integrated automation

- Unbroken information flow

It is not just about supplementing the factory with manufacturing automation tools, but about building an interconnected space in which the software serves as the factory’s “nerve center.”

A proper 360° manufacturing solution brings clarity, efficiency, and accountability to every workflow.

The Four Pillars of Manufacturing 360° (Powered by Weekmate)

a) HRMS: The Fabric of Manufacturing Workforce

Workforce management is among the top problems in the manufacturing industry.

WeekMate HRMS is a manual-labor-saving tool for factories. It automates:

- Attendance and biometric integration

- Shift scheduling and multi-shift rostering

- Payroll accuracy and compliance

- Workforce analytics and performance tracking

It serves as a single workforce management for manufacturing solution that is perfect for the management of contract labor, shop-floor teams, and supervisory staff. Through automation, factories become more efficient and can eliminate errors caused by spreadsheet use.

b) TaskHub: Executing Manufacturing Strategies

TaskHub is the platform’s operational engine. With WeekMate TaskHub, manufacturers can:

- Assign production, maintenance, and quality tasks

- Track deadlines and progress through dashboards

- Automate approvals and updates

- Ensure uniform workflows across departments

TaskHub facilitates task automation for production teams; as a result, delays will be reduced and communication gaps will be avoided. Whether it is a maintenance request or a dispatch task, supervisors receive complete visibility.

c) e-Connect: Streamlining Internal Communication

Fast and reliable communication is a must for a modern factory.

WeekMate e-Connect serves as a central hub that helps consolidate fragmented email threads and scattered chat conversations.

It facilitates collaboration through:

- Central messaging for operations, HR, and admin

- Prompt notifications and alerts

- Communication at the department level

- Live communication for production and quality teams

It functions as a factory communication system that is very efficient in keeping employees aligned from the office to the shop floor.

d) e-CRM: Managing Client Relationships and Orders

In manufacturing, client management is the lifeline, especially in B2B environments.

WeekMate e-CRM brings together:

- The client database and communication

- Order details and delivery schedules

- Invoices, feedback, and interaction history

- Sales pipeline forecasting

This eliminates the distance between sales, operations, and dispatch. As robust manufacturing CRM software, it ensures both teams are on the same page — from the first inquiry to the final delivery.

How Integration Creates Operational Synergy?

The main strength of WeekMate is its integration. The single workflow smoothly moves from one module to another in the following way:

- e-CRM records the details of a new client

- TaskHub creates the necessary tasks automatically

- WeekMate HRMS figures out the available staff and their skills

- e-Connect announces the updates and sends notifications

- The progress is followed live

Such a system creates a connected manufacturing ecosystem that provides departments with a single source of truth, eliminating manual coordination, errors, and delays.

Benefits of a 360° Platform for Manufacturers

A single unified system delivers enormous value to the production line:

Real-Time Visibility

The user gets instant access to workforce data, production tasks, and client updates.

Improved Collaboration

By using internal communication tools within factories, teams can share information seamlessly.

Increased Productivity

Teams share information seamlessly using internal communication tools for factories.

Error Reduction

By integrating the systems, there is no need to enter data twice, and inconsistencies are eliminated.

Scalability

It is very easy to add new team members, processes, or even new plants.

These advantages greatly enhance operational efficiency in factories and act as a catalyst for digital adoption.

Case Example: A Day in a Smart Factory Using Weekmate

Morning

HRMS automatically records attendance and assigns shifts. Supervisors open TaskHub to allocate morning production tasks.

Afternoon

Maintenance work is initiated, and e-Connect immediately sends the corresponding notification. The team is kept up to date on machine status via real-time communication.

Evening

Client delivery schedules stored in e-CRM are linked with dispatch activities. The team confirms readiness and communicates updates without delay.

Result: Fewer errors, quicker communication, higher productivity, and a connected workflow that is complete.

The Future of Integrated Manufacturing Systems

The shift in manufacturing to a new era of AI, IoT connectivity, and predictive analytics will see integrated SaaS platforms evolve into more advanced systems.

- Factories will be heavily dependent on:

- Condition monitoring of machines using IoT

- Intelligent production scheduling software

- Maintenance performed based on prediction

- Automation of HR processes in connection with HR automation for manufacturing

This shift to a digital-first approach marks the beginning of a complete manufacturing digital transformation; thus, factories will be future-ready.

How Weekmate Delivers the Manufacturing 360 Vision

Weekmate is a single software that combines the power of automation, integration, and simplicity in one all-in-one software for factories. Its portfolio — HRMS, e-Connect, TaskHub, and e-CRM — gives the power to manufacturers to:

- Control operations from start to finish

- Enhance task transparency

- Strengthen customer relationships

- Improve labor management

- Speed up decision-making

The platform is a pretty flexible one in addition to being scalable and intuitive — thus, it is among the best SaaS for manufacturing companies that are looking for digital modernization.

Conclusion: Building the Connected Factory of Tomorrow

Unified platforms are the new standard of operational excellence in an industry where every second and each workflow matters. A 360° manufacturing platform leads to better collaboration, higher accuracy, and seamless efficiency.

Moreover, it addresses crucial questions such as what a manufacturing management platform is, how to automate manufacturing operations, the benefits of integrated factory software, and how HR, CRM, and task systems improve production.

Put your factory in charge of a connected future — learn how Weekmate can synchronize your workforce, clients, and communication into one formidable system.

Frequently Asked Questions

1. What modules does WeekMate offer?

WeekMate is a complete suite that includes WeekMate HRMS, TaskHub, e-Connect, e-CRM, and an Email Marketing tool. These modules help you manage HR, tasks, internal communication, customer relationships, and marketing with seamless, custom migrations.

2. Does WeekMate charge per user or monthly?

WeekMate does not charge per user or on a monthly basis. It follows a one-time license model with no per-user limit and no hidden subscription costs, making it a highly cost-effective and scalable solution.

3. Is WeekMate suitable for manufacturing teams and factories?

Yes, WeekMate is an excellent fit for manufacturing enterprises. Its modular SaaS tools help streamline employee management, task operations, internal communication, and client management, making it ideal for production-focused environments.

4. How secure is WeekMate, and what uptime can I expect?

WeekMate is built with enterprise-grade security, including data encryption and role-based access control. It delivers a 99.9% uptime SLA along with 24×7 technical support for uninterrupted operations.